HVAC Components Brazingnts

Gas flame heating Brazing Machines

Various brazing machines are used for

brazing HVAC machine parts. In addition, welding, soldering machines and various assembly machines are being built to easily assemble these parts.

Aluminum or copper coil Brazing

Machines.

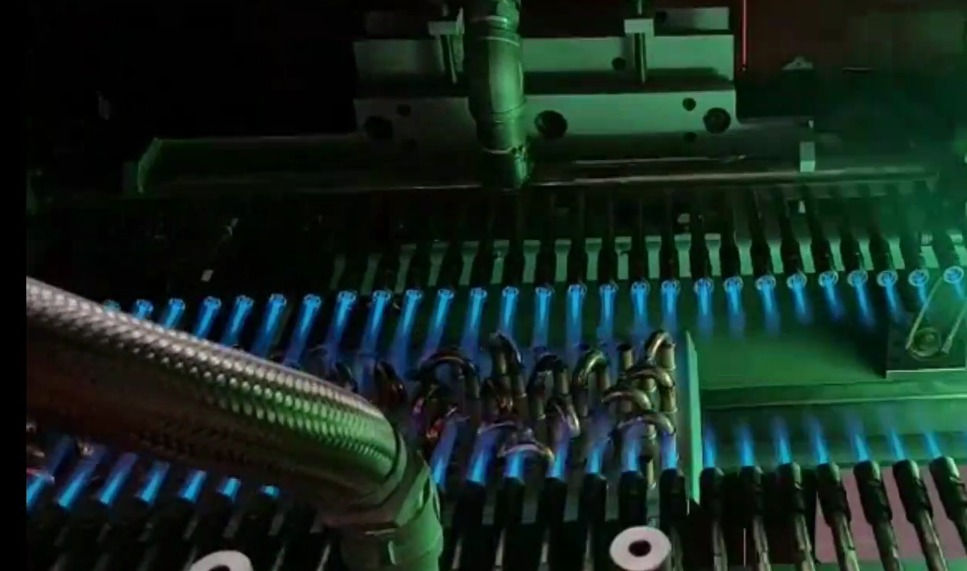

SK Brazing has built several types of gas

flame heating coil brazing machines for

brazing the U-bends of copper heat

exchangers and aluminum heat

exchangers.

Torches that move up/down with a fixed machines slat conveyor.

Coil brazing

machine types.

SK Brazing coil brazing machine

characteristics.

• 2 or 3 stage flame control types

• Orange peel free design by precise

flame control

• Less erosion by precise flame control

• Good memory unit for torch height

and width, flame condition, conveyor

speed, etc.

• Precise flame control provides ideal

conditions for brazing.

• Easy model changeover.

• Leak free joints by providing a good

brazing diffusion condition with heat

balance between the U-bends and

coil body.

• High brazing speed.

Automotive Component

Brazing Machines.

Various brazing, welding, soldering and assembly machines are used for brazing automotive mechanical parts. In particular, it is used for brazing various aluminum, stainless steel and steel parts.

These machines have various

advantages:

- Special torch design for uniform heating.

- Automatic torch position change.

- Automatic flame change function.

- Rotation/up-down flame oscillation.

- Three-stage flame control function.

- Elimination of orange peel crack and

erosion.

Automotive Component

IHX assembly brazing

machine with bending tubes.

In order to braze various IHX joints in bending condition, SK Brazing has been producing many styles of brazing machines, as follows.

One pair IHX bending tube brazing machines.

These machines are widely used for the brazing of IHX tube joints in bending condition. They are designed as one pair to improve the production rate. An operator can load at teach station of the brazing machine in the shuttle. This machine can braze from one to several joints (over 10 joints) at each station in the shuttle. SK Brazing is the first in the world to develop this capability.