Bending machines

SMALL SERIES

up to Ø 20 mm

Tube bending machines from the Small series are extra-compact, and able to process tubes with very small diameters in aluminium, hybrid or extra-long. With operator configured right or left bending directions, or integrated double direction bending, machines from the Small series can adapt perfectly to all production needs, even where integration is needed in automated work cells or if integrated loading / unloading is necessary.

CLEVER SERIES

Single bending head, double bending direction, maximum autonomy.

The tube bending machines of the Clever series represent the Crippa’s solution for the processing of small steel tubes. Right or left in cycle, CLEVER tube bending machines offer patented solutions to reduce cycle times and simplify the production process, ensuring excellent bending quality.

LINEAR SERIES

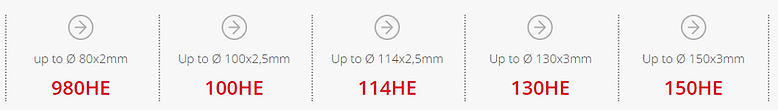

up to Ø 150mm

-

Tube bending machines from the Linear series have small bending heads that allow them to create particularly complex geometries in a single work cycle. These machines can form multistack and multiradius bends with manually reconfigurable bending direction, and can made bends with CLR/DIA ratio even less than 0.8. The nine controlled axes that govern the machine’s movement are driven by absolute digital electric motors with Full Electric technology and controlled by a CNC Siemens 840D sl.

UP&DOWN SERIES

up to Ø 55mm

Tube bending machines in the Up&Down series feature a double bending direction that makes it possible to use only one machine, without operator intervention, to complete tube geometries that usually require post processing operations. This provides considerable advantages for both productivity and precision. The movements of these tube bending machines can turn the tube in the space during the process, eliminating interference with the machine or with the geometry of the part being produced. The nine controlled axes that govern the movement of Up&Down are driven by absolute digital electric motors with Full Electric technology and controlled by a CNC Siemens 840D sl.

UP&DOWN SERIES

up to Ø 150mm

Tube bending machines from the Heavy series stand out for their rigidity and precision, which ensure high level performance and maximum repeatability in heavy processes. The small dimensions of the bending heads and, in particular, the movements that these machines make, allow them to process complex tube geometries in a single cycle. Normally, finished pieces would require a double bending direction or post-processing operations. Furthermore, the high vertical excursion of these tube bending machines makes it possible to increase the number of processing levels, and despite their impressive dimensions, these machines ensure high energy savings.